The company Sentien is behind the development of elegant headphones with bone conduction, voice control, and customization options.

During the development of a new generation of the device, Sentien sought a partner capable of producing prototype parts with high accuracy, functionality, and a focus on design. Together with cotu®, they created a set of high-quality prototypes ready for both testing and presentation of the final product. They focused on the combination of rigid and flexible parts, precise fitting, and aesthetic design with a view to future series production.

This case study aims to provide an overview of the individual stages of product development – from prototyping, through solving production challenges, to preparing for mass production and debugging key production steps.

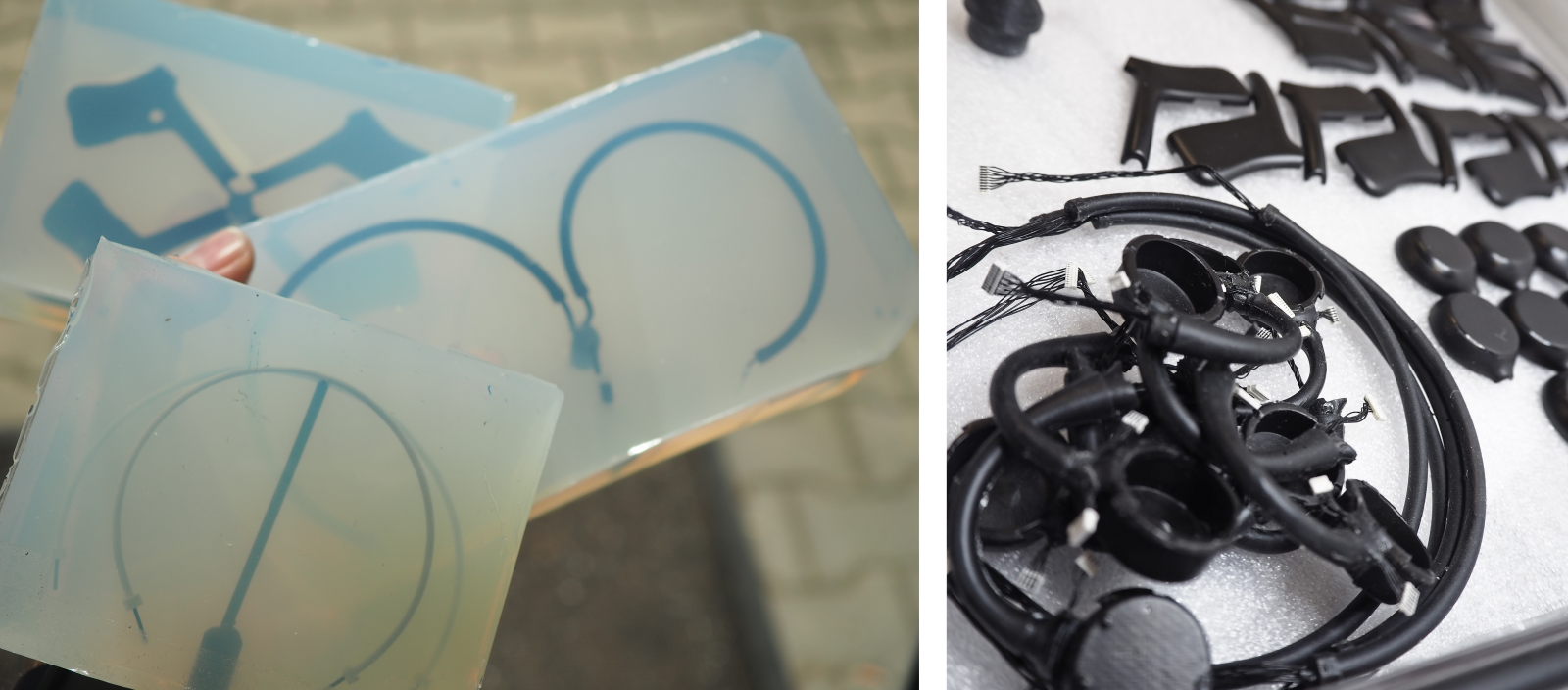

Based on the customer’s input of 3D data, cotu® took over the entire production process. They first optimized the models and prepared master models using stereolithography. These were used for multi-stage vacuum casting of plastics into silicone molds. The final phase included surface treatment of the castings according to the required visual and functional parameters. The project also involved the production of custom jigs and several iterations of manufacturing procedures to achieve maximum precision and repeatability.

How cotu® decided to approach the challenge

Technology used: ASIGA MAX 3D printer, vacuum casting

Material used: Asiga PlasGray V2 and Asiga Denta Model

Production of master models

The customer provided 3D data, which cotu® adjusted before printing with respect to the technological requirements of SLA 3D printing and vacuum casting. Geometry and design details were optimized to ensure accurate printing, casting, and perfect fitting.

After the final data adjustments, master models were produced using SLA 3D printing on the ASIGA MAX 3D printer. All parts were printed with 25 μm resolution using Asiga PlasGray V2 and Asiga Denta Model materials to ensure maximum accuracy and detail.

To ensure dimensional stability during polymerization, the models were cured in a glycerin environment. This resulted in consistent outcomes without deformation and allowed for further post-processing.

Each part underwent careful surface finishing, which included smoothing, surface unification, and final coating in matte or glossy black, depending on the desired visual effect. Special attention was paid to parts connected into a single unit (e.g., transducers or parts of the battery case), which had to be processed without separation to avoid damage to edges and precisely fitted surfaces.

Production of silicone molds

After completing the master models, cotu® proceeded to produce silicone molds for vacuum casting. Depending on the type of part and desired configuration, two types of silicone were used:

- Stiffer silicone – for the first mold series with simple separation and multiple cavities (e.g., transducers in a 4-cavity layout),

- More flexible silicone – for the second mold series where higher elasticity and more accurate definition of parting lines were needed.

The molds were designed as multi-cavity to enable efficient production of multiple pieces at once. Parting lines were defined based on the shape logic of the parts, either directly in the master model or mechanically using tape or a scalpel during mold production.

In some cases, molds were supplemented with air vents, gates, and custom jigs that allowed stable positioning of cable bundles or wires before casting.

Casting of functional parts

In the production of functional parts such as transducers, ear frames, and back frames, rigid polyurethane was combined for solid parts and flexible rubber for elastic zones. The process was adapted to the specific requirements for mechanical properties of each part.

For transducers, casting was first done in two components – a hard shell and a soft inner part separately. In the second version, the entire body was cast from one material in a vacuum chamber. All castings were then cured in an oven to achieve the required strength.

For ear frame and back frame parts, wire reinforcements and cables were cast into rigid polyurethane, followed by flexible rubber. 3D-printed jigs were used for precise placement of components. Connectors were protected using water-soluble filament, which was easily removed with water after casting.

Each manufactured piece underwent detailed visual and functional inspection.

Final adjustments and assembly

After removing the parts from the molds, mechanical finishing followed, including:

- Removal of gates, air vents, and flash in the parting line area

- Precise alignment of mating surfaces, especially for transducers composed of two parts

- Inspection of geometry, edges, and surface quality – no scratches, deformations, or visual defects

In areas intended for mounting electronics and connectors, clean and precise fitting was required to allow the installation of transducers and their closure. For the second version of transducers (rigid PU on both sides), cotu® also performed local polishing of contact surfaces using fine cloth and mechanical polishing to a high gloss. To avoid damaging surrounding areas, a special jig was prepared to precisely define the polished area.

Optimization using 3D printing

During production, the cotu® team adjusted both the part design and the manufacturing processes. As a result, they gradually increased accuracy, repeatability, and reduced scrap rates.

For ear frame and back frame, they switched to more efficient casting using 3D-printed jigs, which helped precisely fix cables and reinforcements. Adhesion between materials was improved by modifying the molds and more accurate placement of wires. For safe casting of connectors, water-soluble filament was used, which could be easily removed after curing. The parting lines of the molds were designed to make component insertion as simple as possible and avoid deformed castings.

The result was more stable production with less need for additional post-processing.

Result of the collaboration and client benefit

Cotu® delivered to Sentien a set of functional prototypes ready for testing the structure, ergonomics, and appearance of the final product. By combining SLA 3D printing, vacuum casting, and custom jigs, they met the demanding requirements for mechanical strength, precise fitting, combination of rigid and soft materials, and high aesthetic standards. The result was a validated manufacturing concept suitable for the next step – series production.

Thanks to the capabilities of SLA 3D printing, technical know-how, and the ability to work with various materials, cotu® can now realize similar projects fully additively, without the need for vacuum casting.

The prototypes described above are now a real product. The final version of Sentien headphones and the option to order them can be found at www.sentienhq.com.

cotu® provides clients with a complete production infrastructure – from technical consulting and 3D data adjustments to the delivery of accurate and visually high-quality parts ready for use. Each project is handled individually with emphasis on functionality, efficiency, and long-term reliability. With top-tier SLA printing and extensive experience in production optimization, cotu® offers solutions tailored to your specific needs.

Looking for a partner for the development of functional prototypes or series production?

Get in touch with us – we’ll be happy to explore your needs and propose a custom solution.