RELMAG electronic s.r.o. has a leading position on the market in the field of reed technology in the Czech Republic, mainly thanks to its thirty years of experience and the background of its own production plant. RELMAG represents a reliable partner for the production and sale of reed relays, sensors, contacts and permanent magnets, including custom designs.

The challenge faced by RELMAG was the customer's need to develop relays for very specific purposes with very specific requirements tailored to their particular application within series production. Standard processes such as plastic injection were not only economically inefficient but also time-consuming with a lead time of 6 weeks. This challenge required not only an innovative solution but also a partner with technological know-how. RELMAG decided on Cotu's 3D printing service and additive manufacturing, namely DLP 3D printing technology, which was considered the optimal way to meet the customer's requirements.

How Cotu decided to solve this challenge

Technology used: Asiga PRO 4K

Material Selection: LOCTITE 3D 3843 HDT60 High Toughness Matte Black

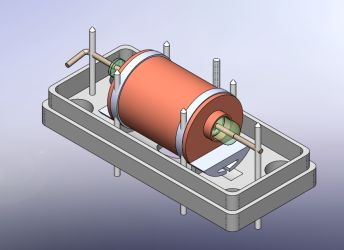

Cotu focused on the selection of optimal materials for 3D printing and decided on Loctite 3D 3843 HDT60, which is the best solution to meet the requirements for components, especially from the point of view of electromagnetic parameters. This material offers the characteristics of a high-strength plastic, similar to ABS, with good impact resistance and excellent surface finish. The newly designed relay components were produced using this material and the DLP printing process on the Asiga PRO 4K printer. By using an additive process instead of injection molding, up to 250 parts could be printed in a single 90-minute print job, proving that the use of photopolymers is far more efficient than other technologies while still providing the superior surface finish and dimensional accuracy required for these custom-designed parts. The 3D printing process thus made it possible to go through all phases of production, from prototyping to serial production of final parts.

The benefits of this solution were significant. By eliminating the need for injection molds, Cotu significantly reduced production costs and shortened lead times. Producing smaller batches using injection molding would incur huge costs per part for this batch. The lead time has also been shortened dramatically. Previously, the mold took approximately 6 weeks to produce, but thanks to 3D printing technology, all parts could be printed in four 90-minute 3D printing jobs.

An essential element in the production of these parts was the use of the Asiga PRO 4K printer, thanks to which it was possible to print regular and flawless parts without supports and subsequent grinding. This printer also has integrated sensors, which is why it was possible to print components with exact tolerances for fitting metal pins - contacts. This would be practically impossible with LCD technology, which does not contain sensors, and therefore would not allow such a level of accuracy and repeatability to be achieved in mass production. The sensors on the Asiga PRO 4K printer were a key element in enabling repeat production with consistent quality of the final parts.

Overall, it can be said that the success of this project lay not only in quality materials and the printer but above all, in the technological capabilities of the Cotu company, which provided a comprehensive solution for serial production, efficient printing and significant cost savings. Thanks to 3D printing, it was even possible to implement such a project.

‘’3D printing has opened a new door for us - to develop and produce smaller batches of products that are far from any default of the shelf solutions. Thus, we now have the capability to serve customers running smaller and completely specific projects from now on. We are amazed at how accurate and precise 3D printing can be and how we can use this technology for final products as well. Based on that we now consider integrating 3D printing into our production process.’’

Zdeněk Zamrzla, Product Manager, RELMAG electronic

Do you want to bring your idea to life? Contact us for professional advice in SLA 3D printing. We will design the most suitable material, handle the complete production of your product, or deliver and help integrate the manufacturing process, including the technology.

Learn more about our 3D printing services, explore the consultancy offered, or schedule a meeting directly.

Case study on Loctite website

3D Printing Drastically Reduces Lead Time & Cuts Costs