How to Speed Up Development, Reduce Costs, and Increase Quality

Efficient production planning today is not only about managing processes correctly, but above all about the ability to respond quickly to change.

That is why development teams and manufacturing departments increasingly rely on high-detail resin 3D printing, which has become a key tool for connecting design, testing, and low-volume production.

When properly implemented into the production workflow, 3D printing enables companies to:

✅ shorten development cycles by dozens of percent,

✅ reduce prototyping and tooling costs,

✅ speed up time-to-market,

✅ and simultaneously increase precision and repeatability.

1. Plan from Design, Not from Production

One of the most common mistakes in production planning is using 3D printing only in the manufacturing phase, instead of integrating it already during product design.

➡️ This eliminates the opportunity to test designs at full scale and verify functionality, assembly, or ergonomics.

➡️ A well-designed process includes 3D printing directly at the CAD design stage. Parts are optimized for additive manufacturing, making subsequent processing faster and more cost-efficient.

Practical experience and industrial studies show that integrating 3D printing already in the design phase can shorten development cycles by up to 30–50%.

You can learn more about designing parts for SLA printing in our Services section.

2. Choose the Right Technology and Material for Your Goal

Not every 3D printing technology is suitable for every type of part.

Key questions every manufacturer should ask include:

- What resolution and accuracy do I need?

- Does the part need to be optically clear, mechanically strong, or chemically and thermally resistant?

- Will the part be polished, painted, or mechanically post-processed?

Resin-based 3D printing excels wherever high precision, fine detail, and excellent surface quality are required.

Thanks to a wide range of resins, it can address various needs:

- Mechanically, chemically, and thermally resistant plastics suitable for technical parts exposed to long-term stress or harsh conditions,

- Rigid or highly elastic materials, used for seals, soles, or medical devices requiring either strength or flexibility,

- Flame-retardant and antistatic resins, applied in electronics, rail transport, or aerospace to meet safety standards and protect against electrostatic discharge,

- Castable wax materials for investment casting, enabling fast production of precise metal castings with minimal post-machining,

- Medical and biocompatible materials, offering the highest level of biocompatibility and widely used in dentistry and implantology.

3. From Prototype to Production: 3D Printing as a Full Manufacturing Step

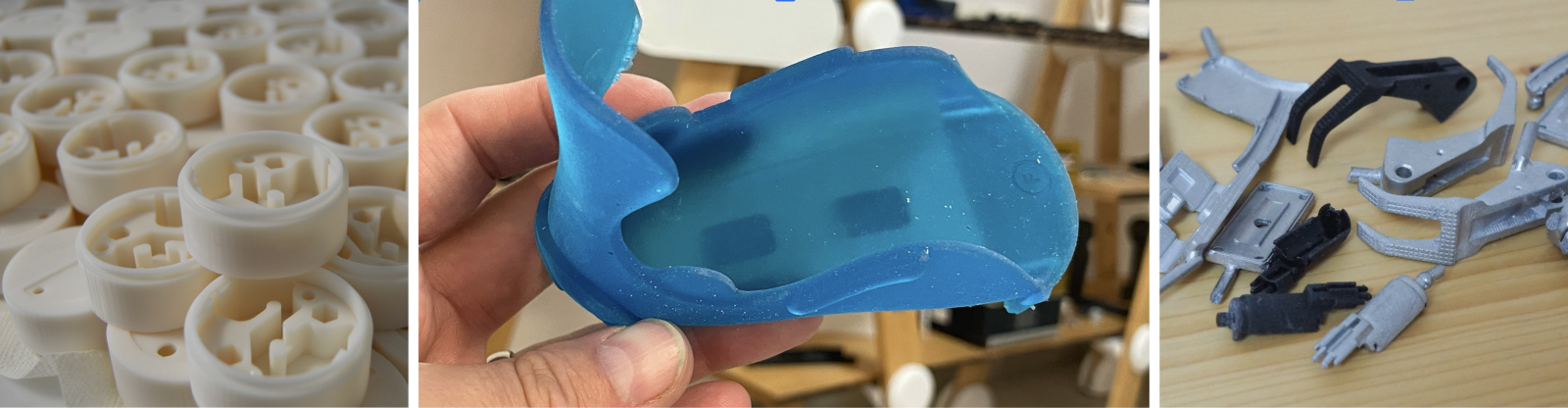

Many companies still see 3D printing mainly as a prototyping tool. In practice, however, it can play a much more significant role — becoming a fully integrated manufacturing step that complements or even replaces traditional technologies.

High-detail resin 3D printing enables:

- production of precise functional parts,

- technical components with high demands on detail and dimensional accuracy,

- assembly and auxiliary fixtures,

- housings, brackets, holders, and small structural assemblies for various devices,

- low-volume and custom manufacturing without molds,

- fast design iterations and variants without investments in tooling or vacuum casting.

The ability to move quickly from prototype to real production significantly reduces time-to-market.

This capability to seamlessly connect development, testing, and manufacturing is one of the areas where cotu has a clear advantage.

Would you like to see a real-world example?

In the Dronetag case study, we demonstrate how high-detail resin 3D printing accelerated product development, simplified design, and enabled low-volume production of final parts. The article also explains how the right material choice and design adjustments helped meet demanding requirements for appearance, precision, and functionality.

4. Capacity Planning: In-House 3D Printing vs. Outsourcing

A critical decision in production planning is whether to rely on internal 3D printing capacity or collaborate with an external partner.

In-house production is most beneficial where 3D printing is part of daily operations — typically in laboratories, design studios, and development departments.

Material subscription programs help keep production running without delays while reducing administrative and logistical overhead. This is an ideal solution for companies that want predictable planning and worry-free manufacturing.

At cotu, we offer both approaches — from consulting, product development, and sales of professional technologies and materials to custom 3D printing and low-volume production.

Explore our Serial Production service.

5. Post-Processing and Quality: An Often Underestimated Phase

Proper production planning does not end with printing the model.

Final part quality is heavily influenced by post-processing steps such as:

- washing and curing, which directly affect mechanical properties,

- polishing and surface finishing to achieve the desired appearance,

- dimensional inspection and tolerance control.

Modern SLA printers use pressure sensors to ensure higher surface quality already during printing, reducing the need for extensive finishing.

Compared to technologies such as FDM or SLS, post-processing in SLA printing can be up to eight times faster and simpler. Nevertheless, it remains a critical part of the process and must be included in production planning.

That is why post-processing should be considered already during job preparation — for example, by estimating curing times and surface or assembly finishing in advance. At cotu, we actively help companies with this: we can estimate these costs, train personnel, and set up processes that are predictable and repeatable.

6. Measurable Results: How 3D Printing Transforms Production Planning

Companies that integrate high-detail resin 3D printing into their production planning achieve measurable results:

- up to 40% shorter development cycles,

- up to 60% cost savings,

- higher quality and repeatability of parts,

- faster testing of new variants and designs.

By incorporating 3D printing into planning, companies gain a predictive process — manufacturing steps can be simulated, time and costs estimated, and changes implemented quickly without dependence on external suppliers.

7. How to Start: From Analysis to Implementation

Successful 3D printing implementation is not about a single machine — it is about a complete system.

At cotu, we combine technology, materials, and know-how into solutions that work long-term. We help companies and development teams to:

- identify suitable applications for 3D printing,

- select the right combination of technologies and materials,

- optimize product development and accelerate the transition to production,

- ensure training, service, and quality control.

Want to make your planning and product development more efficient?

Contact us — we will be happy to review your specific needs and propose an optimal solution.

We help companies turn ideas into reality — from design to final product.