At cotu®, every custom production project is approached with an emphasis on quality, speed, efficiency, and technical flexibility. Thanks to extensive experience in SLA 3D printing, small-batch manufacturing, and prototype development, their team can respond to specific client requirements without unnecessary compromises.

When Kofola approached cotu® with a request for the rapid production of a presentation bottle crate, it was immediately clear that this would be a project testing technical skills, meticulous planning, flawless printing, and the ability to come up with a clever construction solution.

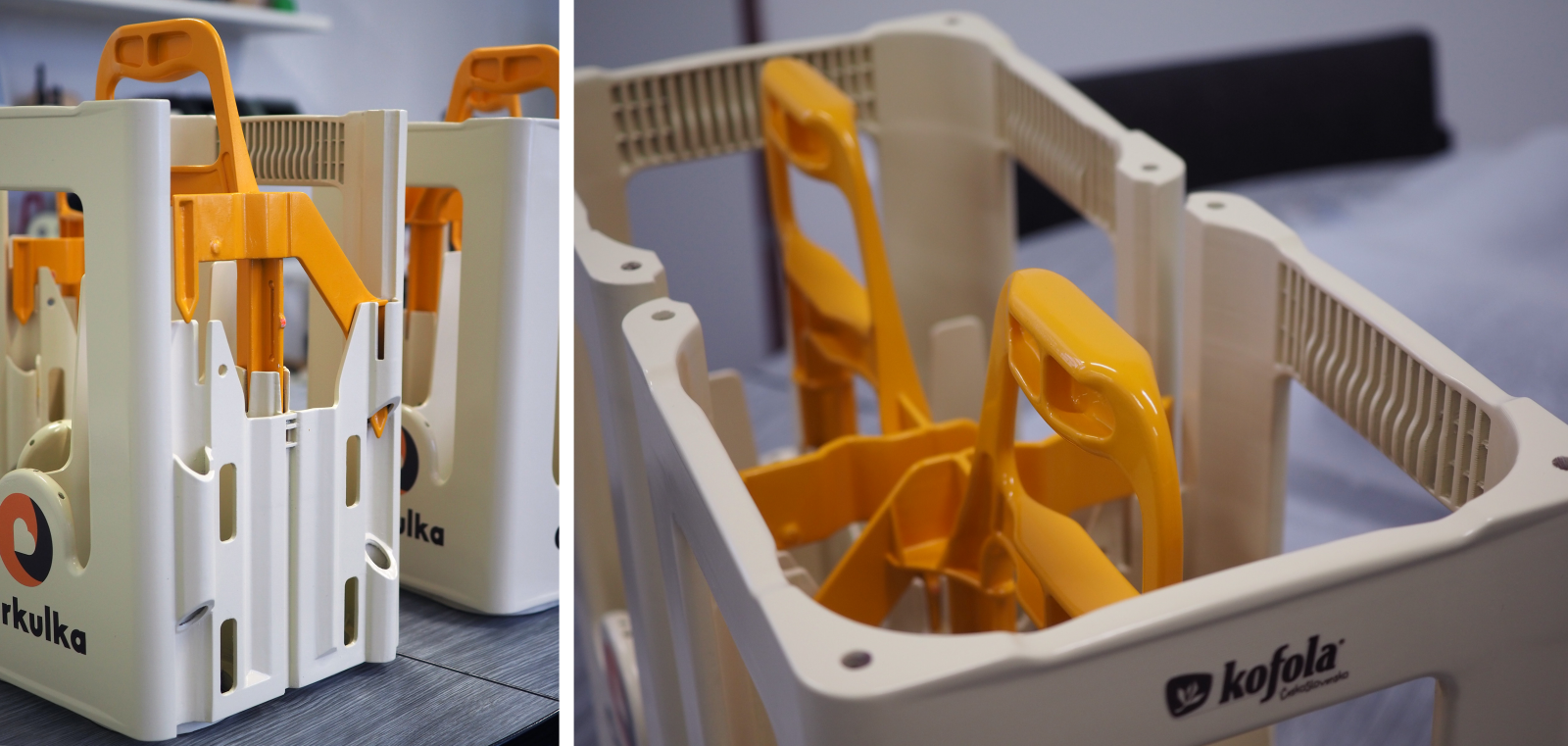

The task was clear: create a large-scale model of a plastic bottle crate for presentation purposes that would match the original not only in dimensions, color, and surface quality, but also in sharp edges and fine details.

The only challenge? There were just seven days to complete the project, during which four crates had to be produced. Given such a tight schedule, printing had to run continuously, including weekends, to ensure on-time delivery without compromising quality.

Since the bottle crate model exceeded the build volume of SLA printers, the design had to be modified and split into smaller sections. The model was optimized for 3D printing so that dividing it into multiple parts would not affect final accuracy, functionality, or quality. At the same time, once glued and painted, the joints had to be invisible, with the surface appearing as one solid piece even under close inspection.

How cotu® tackled this challenge

Technology used: Phrozen Sonic Mega 8K

Material used: Ultracur3D® RG 1100

Splitting the model and preparing the data

In the first phase, cotu® began by modifying the data model. To print all parts in the required quality, the entire bottle crate had to be divided into four segments. The key to seamless assembly after printing was a smart design of the dividing planes. To ensure smooth assembly, the cotu® team designed a so-called puzzle structure that allowed precise alignment of the parts without the need for additional milling or machining.

The model was processed in Materialise Magics software, where it was split into separate parts and print supports as well as dividing planes were precisely generated. The model was further optimized to ensure the fastest possible print while minimizing material consumption.

3D printing with Ultracur3D® 1100 on Phrozen Transform

For production, the team chose the proven SLA 3D printer Phrozen Transform, which allows printing larger objects with high resolution. Printing was carried out using Ultracur3D® RG 1100 resin with a 100 µm layer thickness, which made it possible to achieve:

- high dimensional accuracy,

- smooth surfaces without unnecessary sanding,

- sufficient mechanical strength for handling and assembly.

To meet the demanding deadline, the print setups were designed to allow parallel printing of multiple parts, maximizing the use of the available build area. Special attention was given to the bottle crate handle, which was also divided into several sections to ensure efficient printing and easy assembly. After all parts were printed, they underwent careful manual post-processing – removal of supports, gluing, filling, and final painting in precisely defined shades to ensure the crates met Kofola’s high presentation standards.

What the project tested and what worked flawlessly

The 3D printing process ran completely smoothly thanks to the long-proven combination of the Phrozen Transform printer and Ultracur3D® RG 1100 material, which delivered reliable results even for large-scale projects. The precise preparation in Magics software enabled effective model splitting and support design, which simplified assembly, ensured reliability, and guaranteed shape accuracy. This significantly accelerated the entire process.

Due to time pressure, all stages of production had to be maximized for efficiency. Data preparation, 3D printing of the individual segments, and subsequent assembly ran in parallel on three 3D printers, following a strictly set schedule. Any delay could have jeopardized the project’s delivery, but thanks to careful organization and the well-coordinated cotu® team, the bottle crate models were delivered on time and in the required quality.

Project success summary

The Kofola project confirmed that the right combination of 3D printing, technical expertise, and an efficiently managed process enables achieving top results even under extremely limited timeframes. Thanks to workflow optimization, cotu® successfully delivered complete bottle crate models in the required color, with high quality and a premium surface finish.

The finished crates were ready on time for presentation at the press conference in front of journalists and media. This project also proved that SLA technology is not only a reliable solution for functional prototypes but also for representative presentation models, where precise detail and an aesthetic finish play a key role.

Looking for a reliable and precise solution that works in practice?

Whether you need to design functional prototypes, refine a product design, or ensure small-batch production without unnecessary costs, the cotu® team provides reliability at every stage of development. Rely on an experienced partner who will turn your idea into a functional and aesthetic result – fast, precise, and with maximum care.